WALVOIL’S HYDRAULIC DIGITAL SOLUTIONS READY TO TAKE PART IN THE NEXT BAUMA EDITION IN MUNICH

Walvoil is ready to participate in the next edition of Bauma, the 34th world’s premier trade fair for construction machinery, building material machines, mining machines, construction vehicles, and construction equipment, that will take place from April 7 to 13, 2025, in Munich, Germany.

In line with some of the trend topics for Bauma 2025 and focusing on “Climate neutrality”, “Alternative drive concepts”, and “Sustainable construction”, Walvoil’s Hydraulic Digital Solutions will be featured in Munich in April.

The Walvoil HDS are composed of modules (products, software, systems, applications) focused on energy efficiency towards the ‘ZERO emissions’ trend, development of architectures for safety functions, automation in mobile hydraulics, connectivity and control of operating parameters, human-machine interface (HMI) and an electronic control unit with customizable modular software developed by Walvoil (PHC STUDIO).

They are the direct result of the mobile machinery market demanding lower component complexity and a greater contribution of electronics to ensure greater integration and flexibility of the machine system.

Their benefits are:

- machine energy optimization through reduced dissipation and recovery

- increased safety through improved Human-Machine interface (HMI) and greater operator comfort

- component performance optimization

- reduced temperature and noise

- broad synergy between product and functionality through connectivity and control of operating parameters.

Below a few samples.

ALS - ADAPTIVE LOAD SENSING SYSTEM IN ITS EVOLVED VERSION

Hydraulic systems represent the core actuation of many construction machinery. This technology is well

established in the market and is well known to be reliable and cost effective. Several mechanical control systems

have been developed in the last century, relying on pure mechanical regulators and controllers. Walvoil introduces

a new generation of control systems based on electronic circuit and algorithms. An advanced software allows

better operation performance and dissipation reduction.

To limit the energy dissipation of the hydraulic system the component manufacturer developed variable

displacement pumps: a hydraulic power generation unit that produced the needed flow from hydraulic operator.

This development together with the displacement control system allowed important savings. Among those system

the most common control in construction market is the Load Sensing design: a hydraulic signal provides the flow

request to pump regulator. This system is well known but has additional costs and complexity, for those reasons

a good portion of constant displacement pumps is still used on the market. Walvoil ALS - Adaptive Load Sensing

System, presented in its evolved version, replies to the need of more advanced controllers that minimize the

power consumption without scarifying the operator experience. Thanks to ALS it is possible to modify the system

margin: the control signal for the pump or for the inlet compensator is "corrected” to match different operation

needs.

ALS Solutions: 1- LS Electronic Control, 2- Electronic Flow Control (closed center version), 3-Electronic Flow Control (open center version)

ALS for constant-displacement-systems

The inlet ALS compensator provides adjustable bypass pressure to the flow coming from the pump. In this setup,

the controller limits the power dissipation during idle condition and boost the system in normal operation.

ALS for variable-displacement-system with traditional load sensing piston pump

In those systems a classical LS pump regulator is controlled through the ALS module integrated in the valve,

typically DPX flow sharing main control valve. This architecture provides boost, economy or custom response of

the hydraulic system to the operator request. This technology, already proven in the field allows power demand

optimization and a more tailored operator experience.

ALS for variable-displacement-systems, piston pump with electronic displacement regulator

It’s now possible to integrate ALS also in the piston pump. The electronic controller of the piston pump

swashplate allows a complete electronic control of reaction time and system margin. This system is available for

both open center and flow sharing system, and minimizes pressure drops across the entire hydraulic system.

ALS system applied to a typical working cycle of telehandlers, proved a consumption reduction higher than 5%

and improved vehicle functionalities.

Other case studies:

Case study #1 - Cranes

Hydraulic cranes show different needs based on the operation. In this application, "precision mode” allows very

small flow rates delivered by the valve without affecting spool stroke so the flow resolution. At the same time, the

"boost mode” allows major movement of the actuators and to increase productivity.

Case study #2 - Grader: boost functionality

For this application ALS allows the quick blade reposition and improved control during the machine operation.

Maximum speed can also be related to machine speed or to engine conditions to add extra functionalities.

Case study #3 - Excavator: the needed flow

Excavator application requires several customizations during the tuning. ALS allows a virtual setup of the

machine, with the end user able to tune the machine reactivity based on its experience and type of usage. A

parallel algorithm in this sense provides virtual torque limiter to avoid engine stall and to compensate thermal oil

conditions.

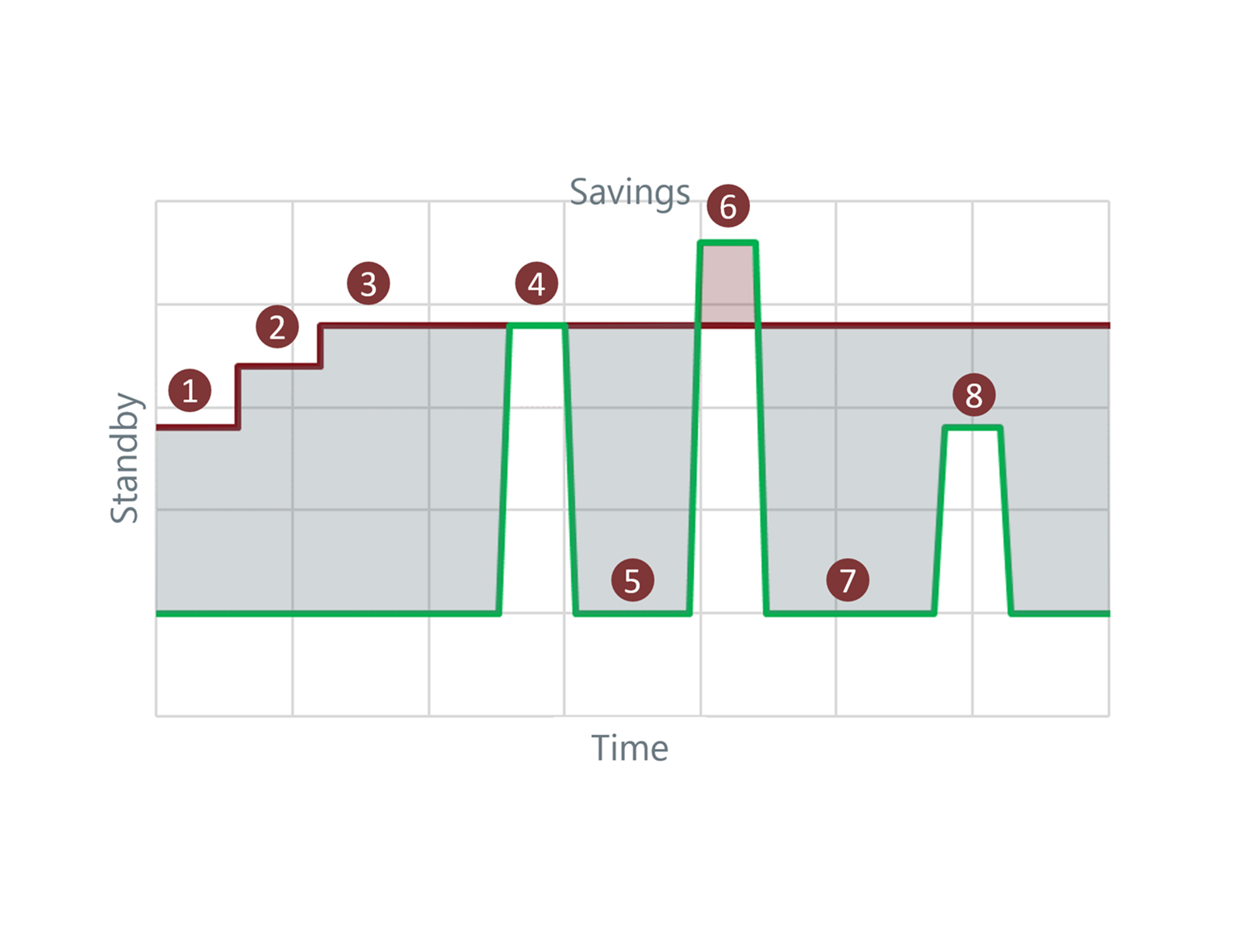

The benefits of the system

• Energy saving during loading/unloading operations in transport.

• Smoother response compared to using unloading valve

• Eco mode enhances efficiency further.

ALS Operations

1. Low Engine Speed

2. Average Engine Speed

3. High Engine Speed

4. Standard Command (Nominal Standby)

5. Transport Mode

6. Boost Mode

7. Transport Mode

8. Eco/Precision Mode (Minimized Standby)

The ALS System received the EIMA 2020-21 Technical Innovation Award, and has since continued to gain market acclaim.

• EPX – ENERGY RECOVERY VALVE

Hydraulic systems have evolved to maximize the predictability of actuation speed. Flow compensation is a well-known technology that mechanically corrects the actuator speed if it exceeds the operator's demand due to

inertial load. This is achieved through a mechanical device introducing a pressure drop to limit the flow when

necessary.

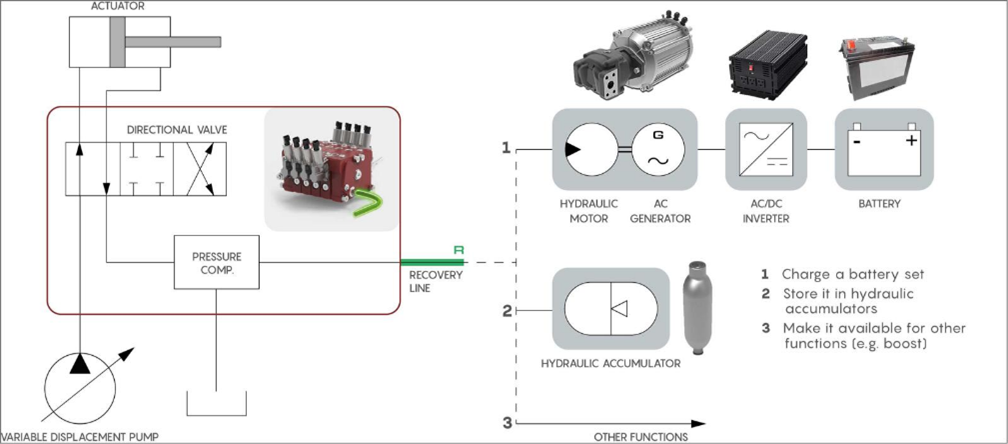

EPX – Complete system

EPX innovates beyond the industry standard with a three-way device that not only limits actuation speed but also

recovers stored gravitational and kinetic energy.

The most common advanced hydraulic systems do include in the main control valve a hydraulic compensator.

This 2-way mechanical device allows to limit the flow rate to the actuator through a restriction. Typically, this

compensator is placed in the delivery line that connects the pump to the actuator inlet. Two technologies are

present now on the market: when the compensator is placed upstream the spools the technology is known as "pre-compensated” systems, vice versa when the compensator is placed "downstream” to the spool, that technology

is called "post compensated” and allows flow sharing operation.

This feature is very useful when the flow request by the operator is more than the pump possibilities: in this condition, the directional control valve maintains the flow repartition between sections. The hydraulic system is then typically completed with counterbalance valves to improve further the actuation precision.

EPX – complete scheme

EPX's approach combines two key innovations.

Meter-out compensation

This design improves the control of unbalanced loads. Meter-out compensation provides extra flow restriction

when the load is unbalanced, preventing unwanted velocities due to the load on the cylinders or motors. This

innovation also simplifies the load control valves: in a meter-out system the meter compensator protects against

load drifting. The secondary valves are used in this case only as safety equipment. These safety valves, typically

flanged on the cylinder, are designed to have minimal pressure drop and minimal impact on regular valve

operation. Example of simplified safety valves are pilot-operated check valve or an electric on/off valve.

Three-way compensation

This patented design introduces an extra flow path to the meter-out compensator. During operation, the

compensator measures the fluid pressure: if the pressure exceeds a determined threshold, an extra path is

opened, pressurizing the recovery line with the stored energy in the actuator.

The combination of these two innovations provides a flow-sharing solution that can recover stored energy in the

machine.

EPX technologies are evolving to minimize the environmental impact and stabilize the power consumption of the

next generation of hydraulic systems.

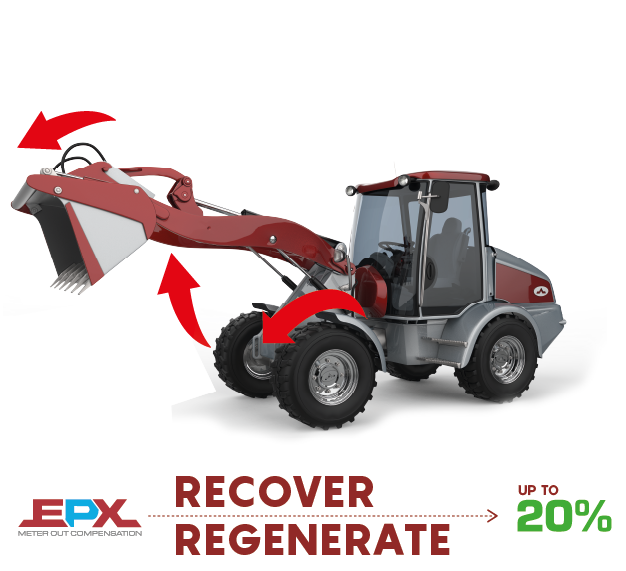

Testing activities on wheel loaders have demonstrated a 20% of energy saving combining recoverable energy and

reduction of compensation losses.

Other case studies:

Case study #1 - Lifter

Industrial lifters are used to move materials in harbours. A typical working cycle has lifting and lowering operation

with and without load. EPX technology stabilizes the power demand of the actuators allowing smaller components

and steady-state operation.

Case study #2 - Telehandler

One of the quickest evolving construction machines, telehandlers represent several challenges: a hybrid machine between a crane and wheel loader needs perfect control of all the functions and low dissipation in short stroke. EPX avoids counterbalance dissipation and provides a source of recovered energy.

Case study #3 - Compact wheel loader

Compact wheel loaders are quickly evolving through electrification allowing their usage in closed and noise

sensitive environments. EPX provides a solution that limits the hydraulic dissipation in the electric application.

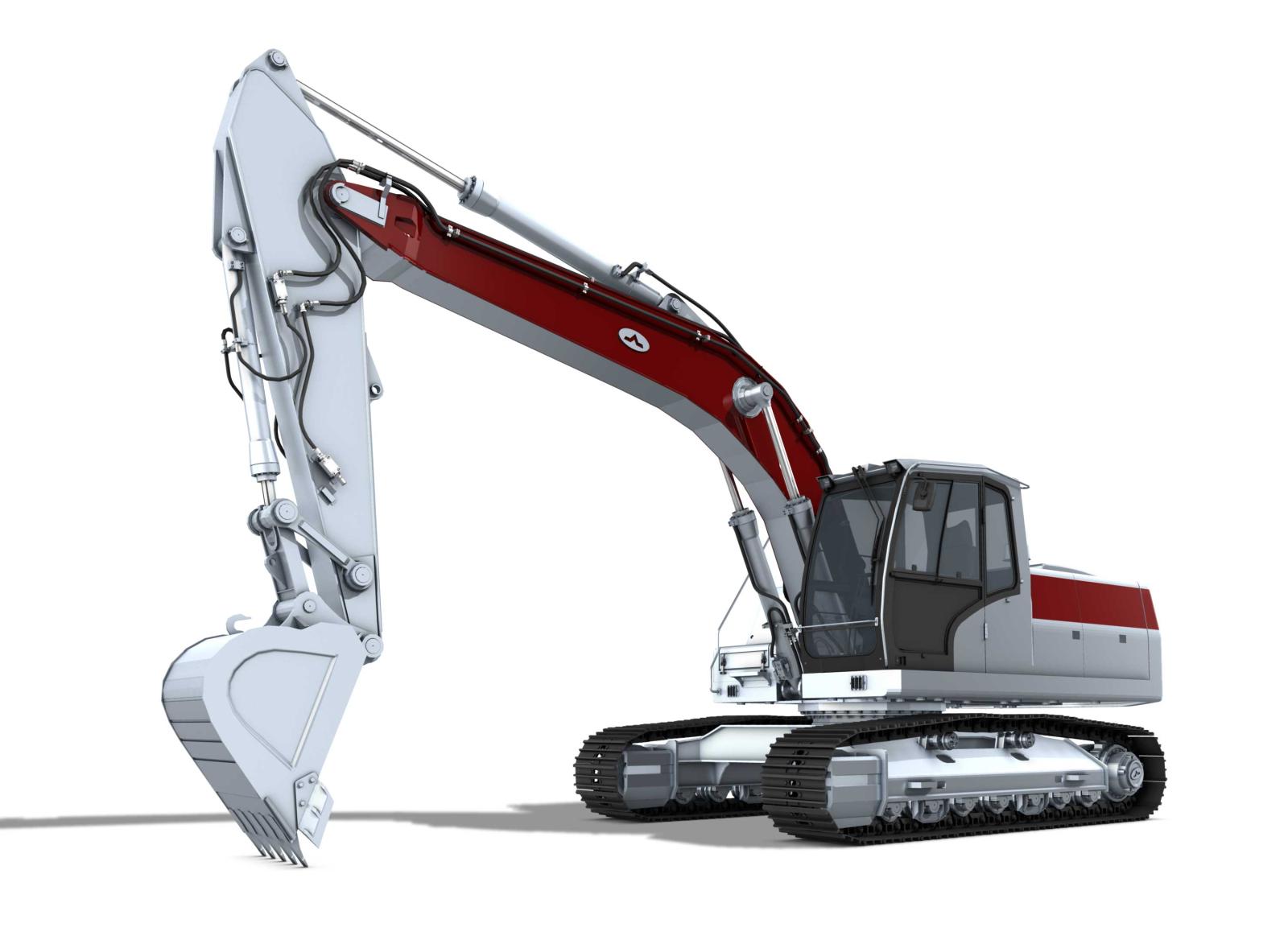

• WALVOIL’S OPERATING ASSISTANCE SYSTEM FOR MINI AND MIDI EXCAVATORS

This operating assistance system for midi-excavators incorporates concepts from the robotics sector into the

control of the hydraulic arms of excavators in order to automate the manual control of each joint to obtain much

higher performance and increase operational safety thanks to the use of features for the generation of trajectories and joint control. With machine HMI, the operator can also create virtual walls that define the safety area where the machine is not allowed to work.

There are many types of off-highway vehicles in the world and all of them can perform several different tasks. All

these machine needs trained operators for their use, especially for more complex jobs that require constant attention and precision.

In addition to carrying out the specific work, the operator must also pay attention to his own safety and to that of the people around him; this can increase his level of stress.

Walvoil’s operating assistance system for mini and midi-excavators incorporates concepts from the robotics sector, where the automation with electrical motors is well studied, into the control of the hydraulic arms of excavators in order to automate the manual control of each joint to obtain much greater performance and increase operational safety thanks to the use of features for the generation of trajectories and joint control.

Machine sensorization

The excavator operations require coordinated movement of the swing, boom, arm and bucket to control the position of the End Effector, centre of the bucket tip, to obtain the desired trajectory. This can be achieved through the implementation of an automatic control system for the excavation task, which requires the understanding of the kinematics, the dynamics, and the control of the excavator.

The desired features are obtained equipping the machine with a minimum of onboard sensors to dynamically monitor the geometry of the machine (6 Degree of Freedom Inertial Measurement Unit), without using external equipment or sensors like GPS or Laser.

These features are obtained thanks to the strong integration of the electronics system with the hydraulic system; to support the robotization task with maximum precision and stability, the hydraulic circuit is based on the latest developed components technologies: a Load Sensing Flow Sharing Main Control Valve with electro-hydraulic controls is provided together with a Variable Axial Piston Pump with electronic displacement control. A dedicated ECU executes a control strategy that achieves the best and most efficient working conditions; a continuously adjusted pump Pressure Margin allows to emphasize the flow delivery smoothness; additionally, a flow control contribution eliminates pressure instabilities and ripples: both control strategies cooperate to a solid foundation for the automatic functions.

Virtual wall example

Example of tasks that can be simplified with this automation features are

- the final grading of a trench for pipe laying (trajectory with -1° of inclination)

- or creation of an embankment (trajectory with 45° of inclination).

The operator defines the desired trajectory with the following parameters:

• Starting point; positioning the End Effector in the desired position.

• Inclination angle respect the horizontal and the vertical offset level; with machine HMI.

The algorithm calculates the trajectory up to the ending point where the joints reach them limits.

Beside the features to increase the performances, there are the ones to improve the safety of the driver, the bystanders, and the others vehicles in the working area.

With machine HMI, the operator can create virtual walls that define the safety area where the machine is not allowed to work.

Automatically the system slows down and stops the machine if the operator accidentally tries to work in that specific areas and allows only movements to return in the correct working area.

These features increase the overall safety of the worksite and the performance of the work while reducing stress

for the machine operator.

Excavator activity with Operating Assistance System

Advantages of the system in brief:

- increase of the overall safety of the worksite

- increase of the performance of the work

- while reducing stress for the machine operator.

Walvoil Communication & Marketing

walvoil@walvoil.com

Tel. 0039.0522.932411

DISCOVER OUR NEW PRODUCTS

DISCOVER OUR NEW PRODUCTS