EPX – Hydraulic Energy Recovery: at bauma and at eima 2022 the new system for recovering hydraulic energy through meter-out compensation technology

Energy Sustainability on mobile machines with the new Hydraulic Digital Solution product line

The modern mobile machinery market demands a constant increase in productivity and performance, together with lower operating costs, greater efficiency and reduced emissions in favour of sustainability and social responsibility.

Walvoil illustrates how to aim for increased efficiency of the hydraulic system and its components, with a possibility of reducing consumption by more than 20%.

Walvoil pursues this goal by acting in 2 ways:

- by reducing consumption and energy dissipation with ALS (Adaptive Load Sensing) systems.

- by recovering energy, which would otherwise be wasted, through EPX (Meter out compensation) technology.

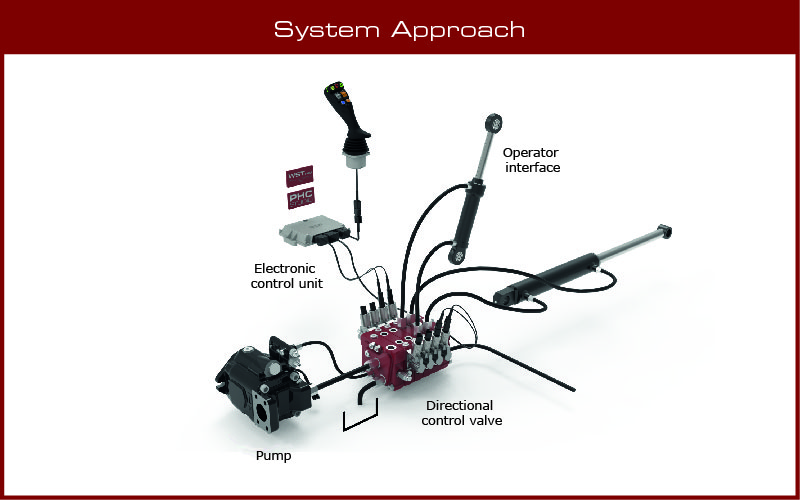

EPX: system approach

EPX technology is made of a Flow Sharing directional control valve, an electronic joystick, a Load Sensing pump and an electronic control unit with customizable modular software developed by Walvoil (PHC STUDIO).

EPX technology is based on new compensator’s function with a recovery line R powered by flow in pressure (Power).

This principle is at the basis of the recovery, which occurs in contemporary movements, in dependant sections at lower loads, and also in single movements with overrunning loads, thanks to a low pressure pilot source X feeding LS line. The downstream compensator keeps independent from the pressure the flow to the actuators and allows recovering energy during simultaneous movements in the sections at lower load and in presence of gravitational loads.

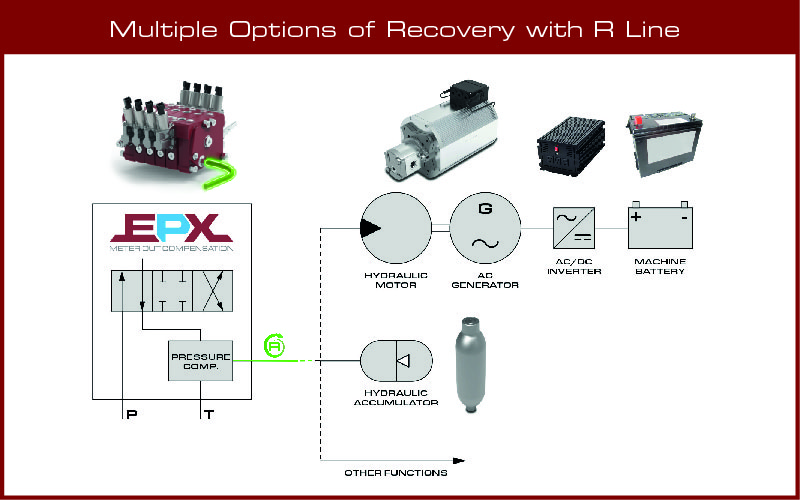

Energy recovery strategy: multiple options of recovery with R line

Once the recovered flow is available in the line R, its management depends on the choices of the equipment

manufacturer.

It is possible to regenerate the recovered flow into the system directly, to store it in a hydraulic accumulator, or to transform it in electrical energy and store it in a battery.

Testing activity

EPX valve has been installed in a hybrid front end loader for tractors, powered by the primary ICE engine and by a secondary boost electric system composed by:

• ICE equipped with primary hydraulic pump

• Electrical Motor (19 kW) equipped with boost

• 600 A Inverter

• Battery charger control panel (CAN-Bus protocol)

• 48 VDC kWh lithium-lon battery.

Test outcome

• 10% energy recharged to battery

• 8% saved with booster overcharge

• 16% energy saved with internal regeneration

Same working cycle performed using only 66% of energy normally consumed.

(Test performed on experimental equipment, under specific working conditions)

Walvoil EPX – meter out compensation technology: benefits

• Traditional Flow Sharing architecture

• Energy recovery options based on OEM’s choice

• Prolonged autonomy and reduced battery capacity on electrified machines.

ALS + EPX: a winning combination

ALS and EPX are two highly flexible technologies that can be combined and add up to their respective benefits.

Variety of configurations and strong electronic integration allow solutions to be adapted to a wide variety of circuit configurations. Different levels of complexity and performance can be achieved thanks to the modularity of the PHC STUDIO software.

DISCOVER OUR NEW PRODUCTS

DISCOVER OUR NEW PRODUCTS