Discover Walvoil’s new operating assistance system for mini and midi-excavators

There are many types of off-highway vehicles in the world and all of them need trained operators for their use, especially for more complex jobs that require constant attention and precision. The operator must also pay attention to his own safety and to that of the people around him; this can increase his level of stress.

Walvoil’s Operating Assistance System for midi-excavators incorporates concepts from the robotics sector into the control of the hydraulic arms of excavators in order to automate the manual control of each joint to obtain much greater performance and increase operational safety.

The excavator operations require coordinated movement of the swing, boom, arm and bucket to control the position of the bucket tip, to obtain the desired trajectory. This can be achieved through the implementation of an automatic control system for the excavation task, which requires the understanding of the kinematics, the dynamics, and the control of the excavator.

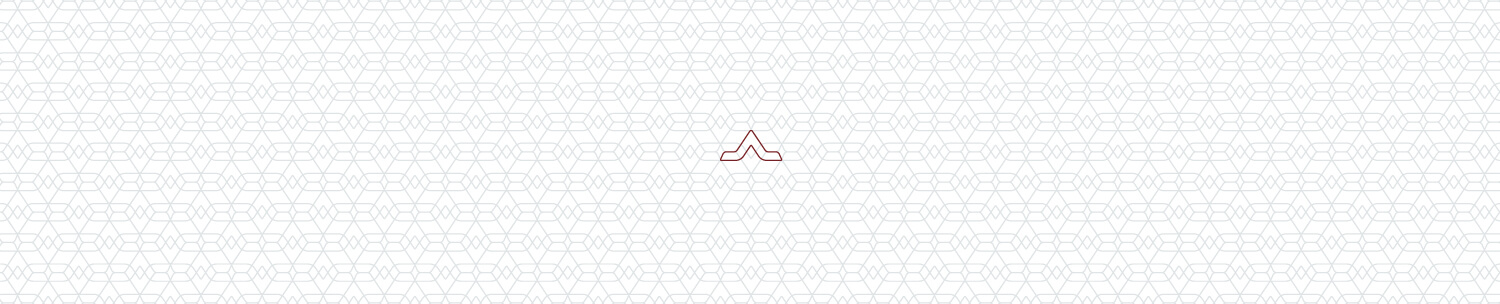

The desired features are obtained equipping the machine with a minimum of onboard sensors to dynamically monitor the geometry of the machine (6 Degree of Freedom Inertial Measurement Unit), without using external equipment or sensors like GPS or Laser.

These features are obtained thanks to the high integration of the electronics system with the hydraulic system: a Load Sensing flow sharing Main Control Valve with electro-hydraulic controls and a Variable Axial Piston Pump with electronic displacement control.

The continuously adjusted pump Pressure Margin allows to emphasize the flow delivery smoothness; additionally, a flow control contribution eliminates pressure instabilities and ripples: both control strategies cooperate to a solid foundation for the automatic functions.

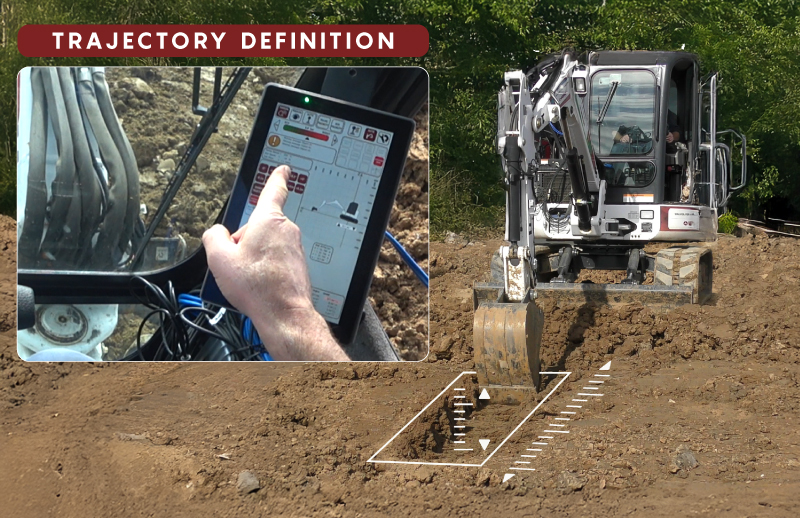

Example of tasks that can be simplified with this automation features are the final grading of a trench for pipe laying or creation of an embankment.

The operator defines the desired trajectory and the algorithm calculates the trajectory and automatically controls the different joints in order to follow it.

With machine HMI, the operator can also create virtual walls that define the safety area where the machine is not allowed to work; automatically the system slows down and stops the machine if the operator accidentally tries to work in that specific areas and allows only movements to return in the correct working area.

These features increase:

- the overall safety of the worksite

- and the performance of the work

- while reducing stress for the machine operator.

DISCOVER OUR NEW PRODUCTS

DISCOVER OUR NEW PRODUCTS