NEW SOLUTIONS FOR FORKLIFTS

In recent years the forklift market has quickly evolved towards more and more sophisticated technological solutions, driven by specific needs such as compliance with international safety regulations, energy optimization to maximize operations and the need for high performance and functionality.

The most important innovations concerned in particular the electronic integration of the systems and, as regards the electric forklifts, the development of sophisticated electric traction systems.

The hydraulic circuit of the forklift, although simple and made up of few components, experienced the introduction of some new technologies as well, even though there are still areas for improvement and optimization of functionality.

WALVOIL, one of the world-leading manufacturers of hydraulic control valves and complete mechatronic systems for mobile applications, has been investing a lot of energy for the development of specific solutions in the last years, with the aim of consolidating its long presence in this market sector.

Walvoil’s product range extends widely among the various possible technologies (cast iron castings with internal channel optimization, manifold/cartridges design, manifolds/parts in body design); this experience, combined with a strong attitude to customization and co-design, allow from time to time to develop the most appropriate product for the customer's functional, energy and economic needs.

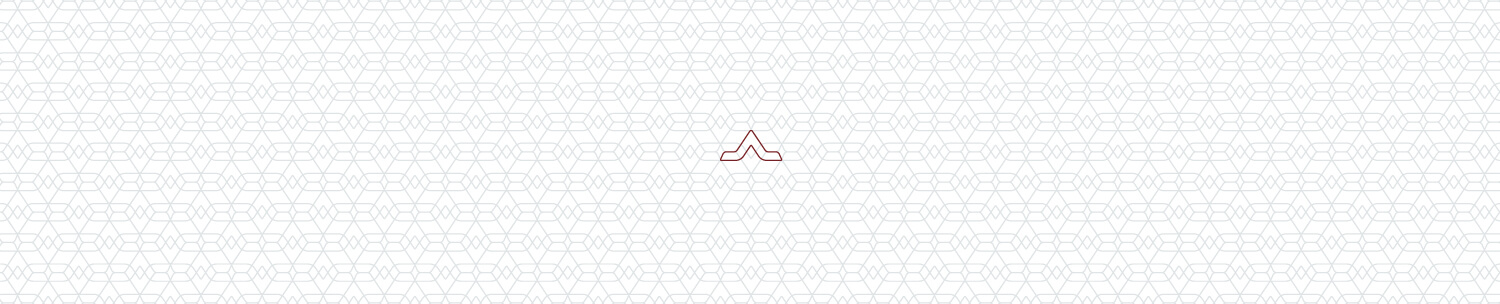

The history of Walvoil is strong in many applications made with Open Center monoblock and sectional valves, mostly manually operated, equipped with specific functions. For example, the SD8 sectional valve shows the following options:

- Inlet cover with integrated priority valves;

- Priority valve with double level of flow for the optimization of consumption on endothermic forklifts with open center power steering;

- Spool for tilting with integrated balancing valve;

- Systems for partitioning the flow in the tilt function.

SD8 – Open Center Sectional Valve

The ISO3691 standard requires the presence of a device that limits the maximum load descent speed. The SD8 sectional valve has recently been equipped with a compensator that makes the fork descent speed independent of the lifted load and therefore allows to limit the maximum speed.

It has been developed to guarantee an adequate descent speed of the first stage even without load on the forks.

The same device also integrates the safety functions that secure no leakage from the load and the need for an electrical consent to allow the descent operation: a thorough study by Walvoil’s R&D allowed to examine different construction solutions, identifying the most effective ones in terms of reliability.

Other families of open center valves are suitable for creating solutions dedicated to forklifts up to 8t, as well as specific applications for Heavy Load forklifts, where valves with flow up to 400 l/min are used.

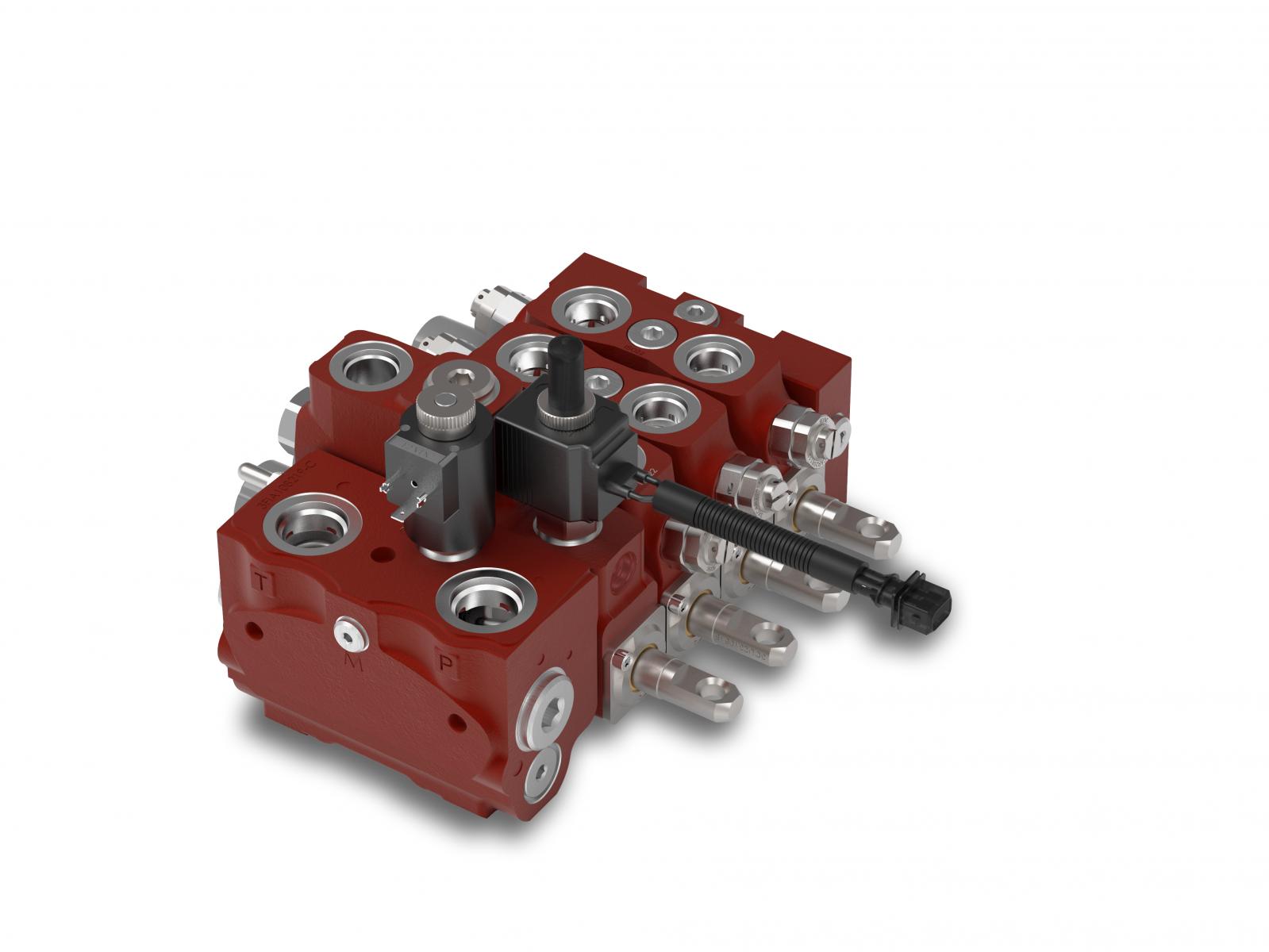

But Walvoil has been concentrating its resources mainly towards the latest generation of electric forklifts: the developed solutions integrate various electrical controls to interface with fingertip controls, meeting the demand for simultaneous movements or multifunction. In order to meet this type of requirement Walvoil implemented its line of flow sharing sectional valves of the DPX series, proposing an unreleased solution for this sector. These valves are of the LS type and can be either open center or closed center.

Each section is equipped with a patented pressure compensator that allows all the active functions to receive oil in all working conditions, even in case of saturation of the pump flow rate. In addition, like all LS valves, the DPX allows to make the speed of the actuators independent of the lifted load.

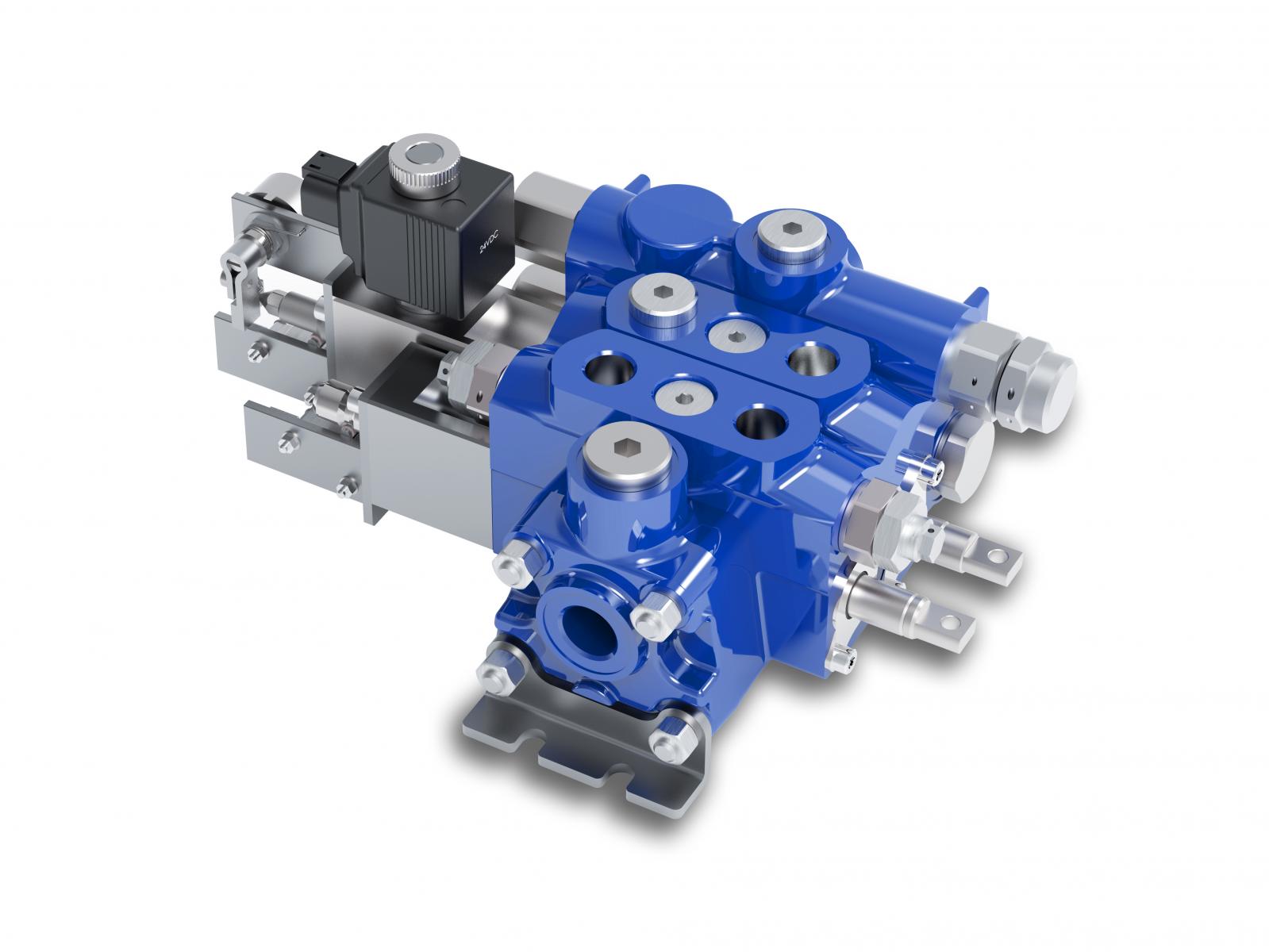

DPX100 – Flow Sharing Load Sensing Valve for open center/closed center

The Walvoil’s R&D together with the Test Department focused on the lifting function, in order to ensure that the forks descend with the engine off, resulting in battery savings and increase in the forklift autonomy. To do this, a hybrid flow-sharing valve has been conceived and tested on the machine, in which the tilt and lateral displacement sections are DPX sections, while the inlet cover and the lifting section have been integrated into a single block. The lifting spool and the relevant electro-hydraulic control have been replaced by the new proportional solenoid valves of the EC series. Together with the new logical elements of the LA series (cartridge compensators), these valves allow a high control of the lifting function.

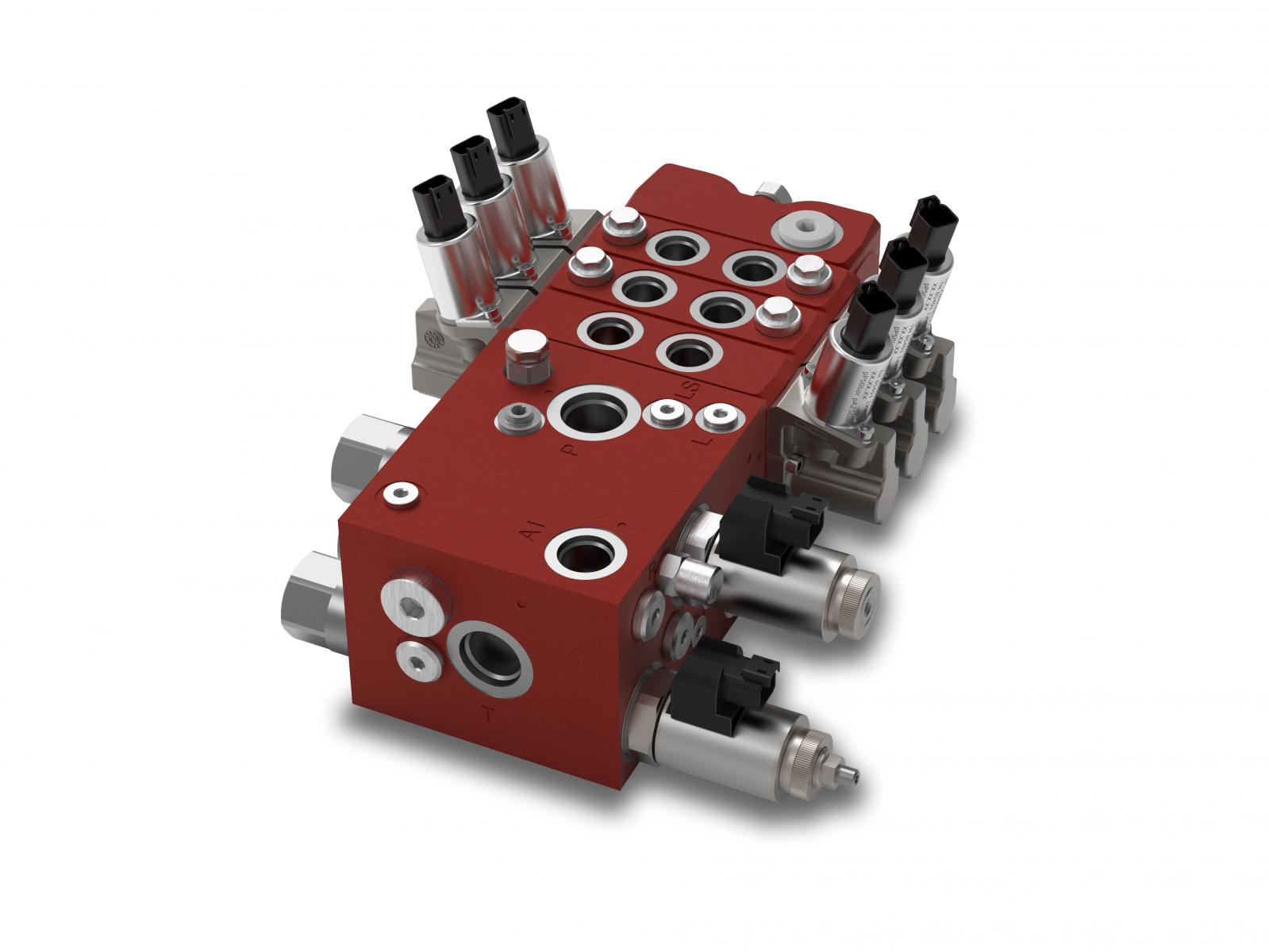

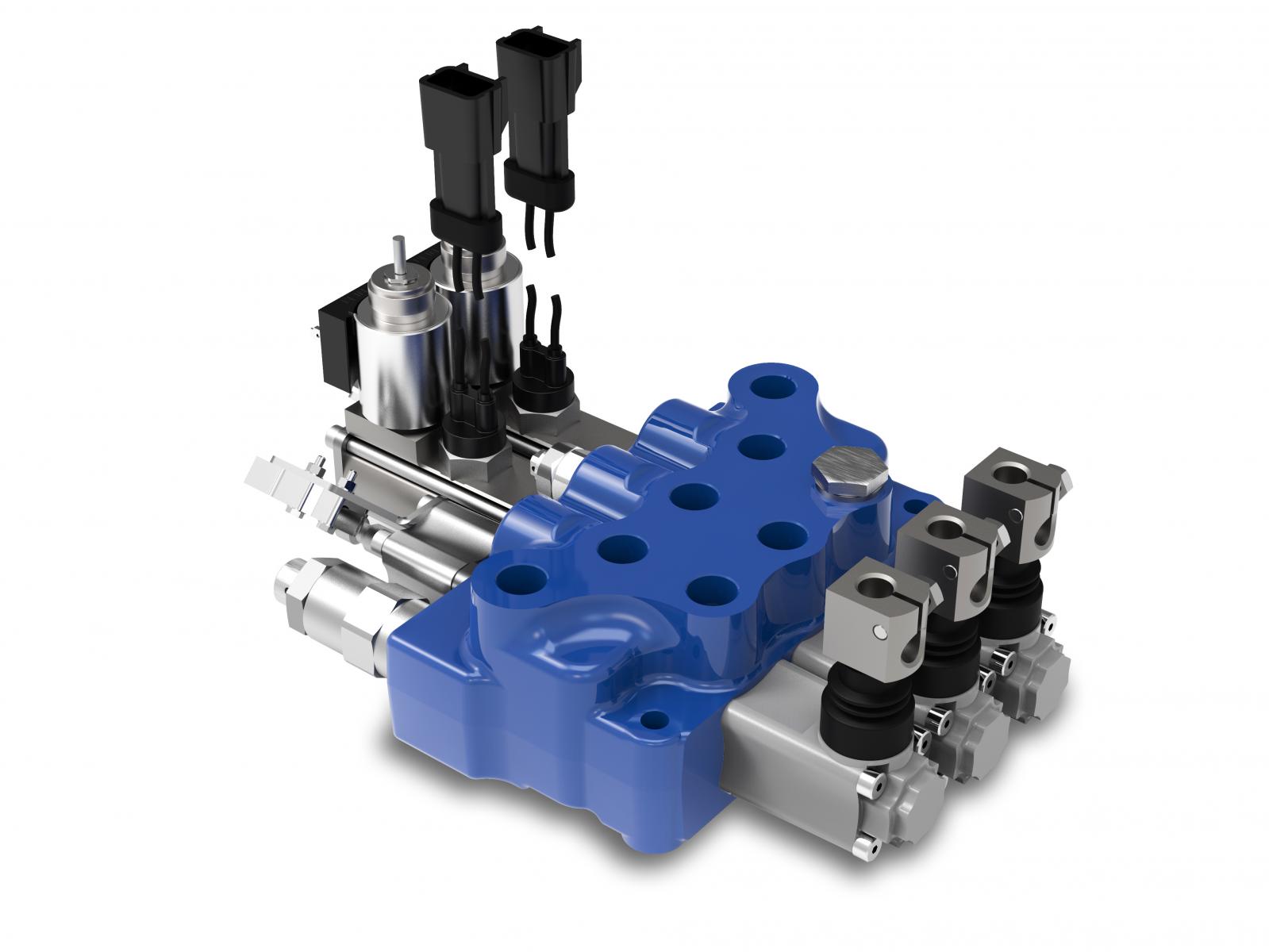

With the aim of covering the range of small-scale electric forklifts up to 1-2 tons, Walvoil developed the 40 l/min SDX060 compensated sectional valve. With its compact design, the SDX060 has a direct proportional electric control with flange auxiliary valves. The local compensator makes the speed of the actuators independent of the lifted load. Also in this case the inlet cover joins the lifting section, which is obtained by proportional solenoid valves, with all the benefits previously illustrated in the case of the DPX valve. An overcenter valve is flanged on the tilt section.

SDX060 – LS Proportional Sectional Valve

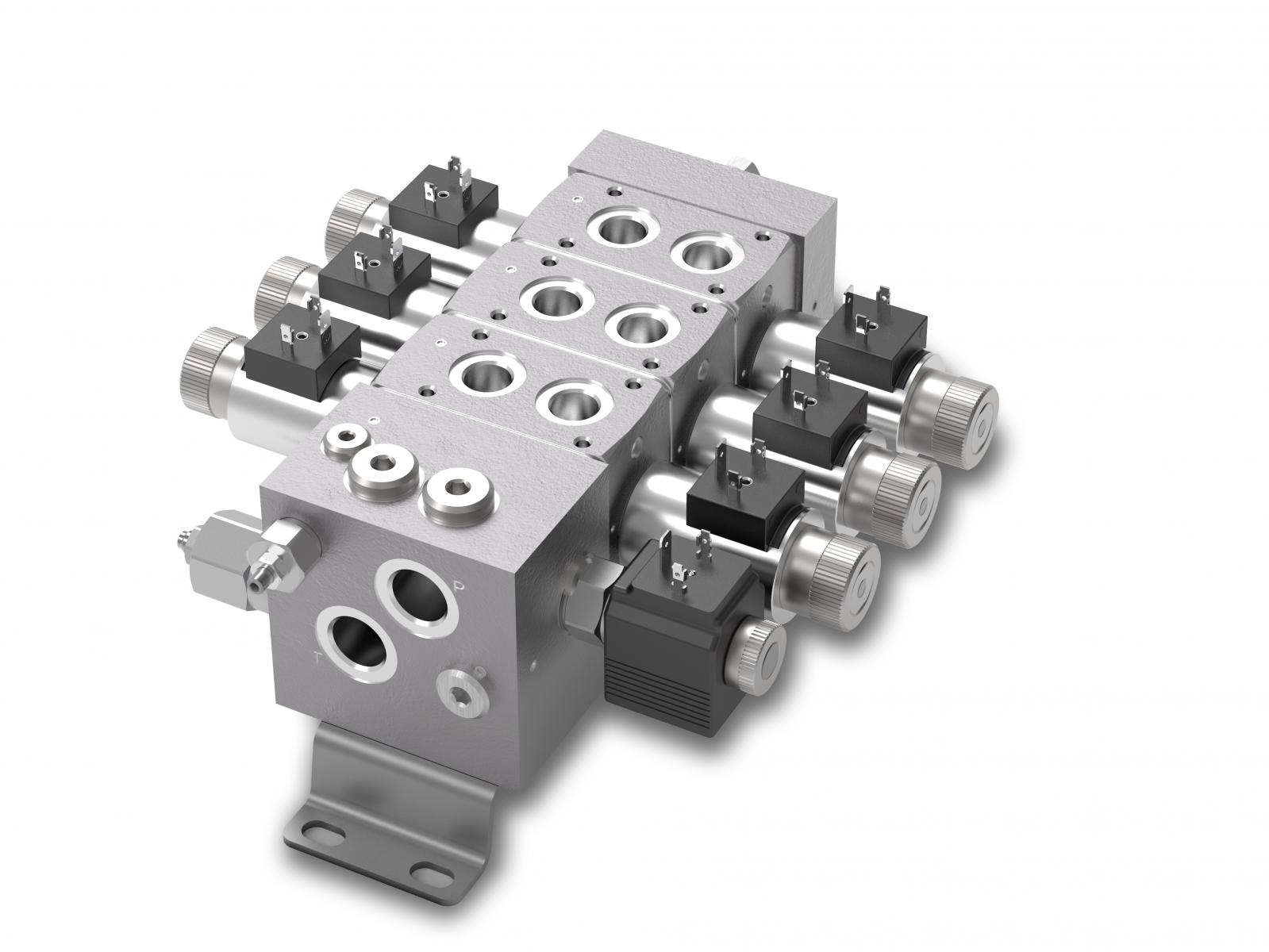

Walvoil’s strong international connotation and the global presence of its production facilities have also allowed the development of solutions strongly oriented towards the specificities of local markets.

New monoblock and sectional valves, specific for the Asian and American markets, have recently been launched, highlighting Walvoil's ability to always balance the technology/cost ratio at its best, thanks to the wide range of products.

DVS10 – Sectional Valve for Open Center FL50 – Monoblock Valve for Open Center

Walvoil’s offer is completed by a series of fundamental electronic products for forklifts such as:

• position sensors on the spools, to detect the oil demand required by the operator and thus allowing to vary the number of revolutions of the electric motor and the flow rate supplied by the pump driven by it (electric forklifts);

• electromechanical actuators based on brushless or stepper motors, capable of operating the spools without hydraulic piloting, useful for example to lower the forks with the electric motor off;

• joysticks and control units compliant with the CANopen and SAE J 1939 communication standards, to dialogue with electric drives, endothermic engine and display;

• joystick with ergonomic multi-function handles;

• programming and calibration software according to the IEC 61131 standard to customize the operation and facilitate the setup on board the machine.

CED400W – IEC 61131 Programmable Electronic Control Unit

CJW CAN Bus JOYSTICK with MTH handle with CANopen or SAE J 1939 communication standards

The ability to develop new products and to adapt existing products to the application together with the strong proximity to the customer place Walvoil as the ideal partner for the design and development of mobile systems such as forklifts.

Walvoil Communication & Marketing

walvoil@walvoil.com

Tel. 0039.0522.932411

CED400_Walvoil

(350 Kb)

CED400_Walvoil

(350 Kb)

CJW_MTH_DX_1ROLLER_2PULS_Walvoil

(662 Kb)

CJW_MTH_DX_1ROLLER_2PULS_Walvoil

(662 Kb)

DPX_Walvoil

(2396 Kb)

DPX_Walvoil

(2396 Kb)

DVS10_Walvoil

(2449 Kb)

DVS10_Walvoil

(2449 Kb)

FL50_Walvoil

(2039 Kb)

FL50_Walvoil

(2039 Kb)

SD8_Walvoil

(2281 Kb)

SD8_Walvoil

(2281 Kb)

SDX_Walvoil

(2326 Kb)

SDX_Walvoil

(2326 Kb)

WALVOIL_new solutions for forklift_Sept2019

(335 Kb)

WALVOIL_new solutions for forklift_Sept2019

(335 Kb)

DISCOVER OUR NEW PRODUCTS

DISCOVER OUR NEW PRODUCTS