WALVOIL HYDRAULIC DIGITAL SOLUTIONS: EFFICIENCY AND SUSTAINABILITY IN AGRICULTURAL MACHINERY

October 2023

WALVOIL HYDRAULIC DIGITAL SOLUTIONS: EFFICIENCY AND SUSTAINABILITY IN AGRICULTURAL MACHINERY

Iacopo Marasi – Application Engineer Walvoil Spa

Hydraulic Digital Solutions

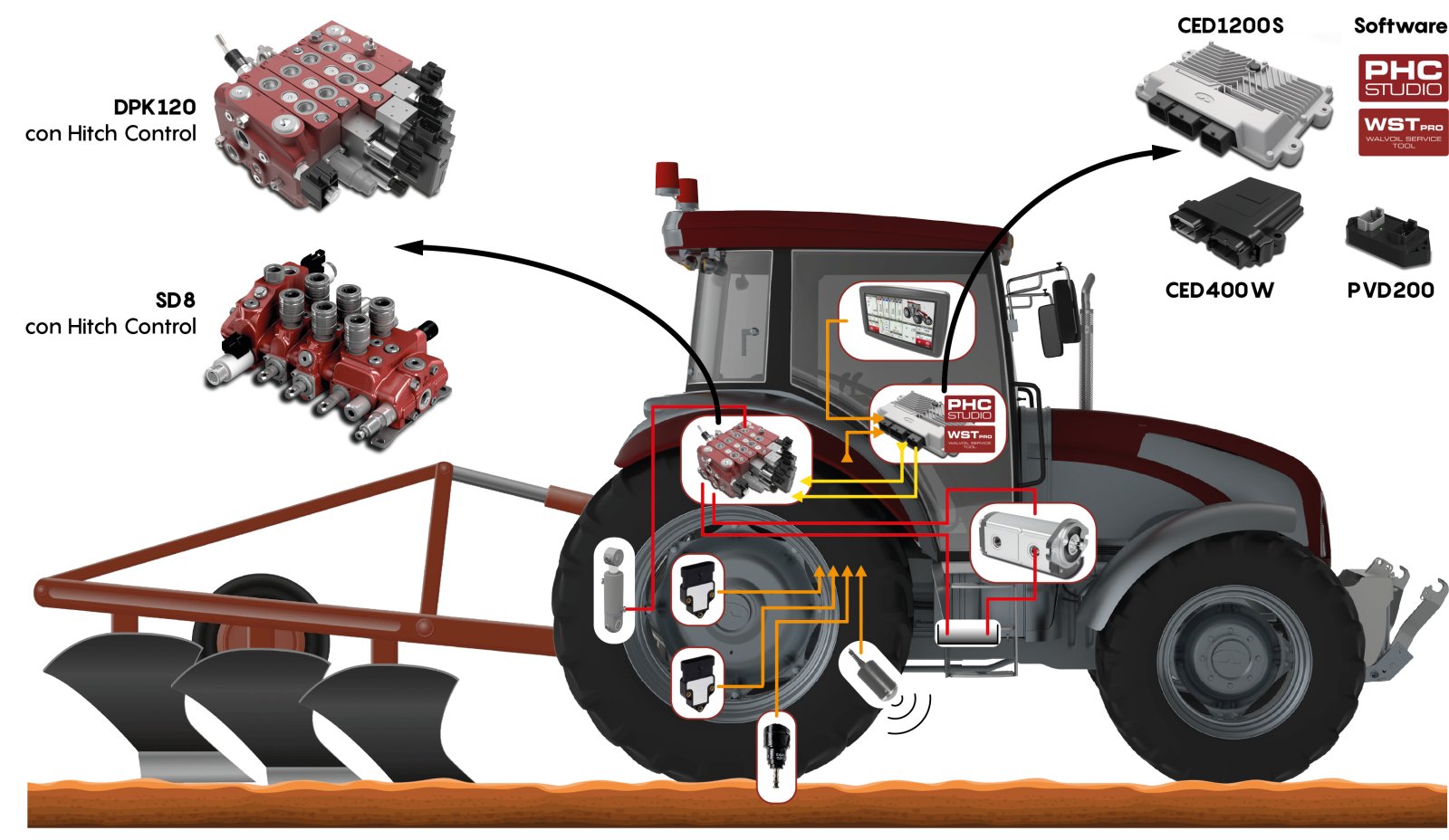

Fig. 1 – Walvoil Hydraulic Digital Solutions

The modern mobile machinery market demands a constant increase in productivity and performance, in conjunction with lower operating costs, greater efficiency and reduced emissions in favour of sustainability and social responsibility.

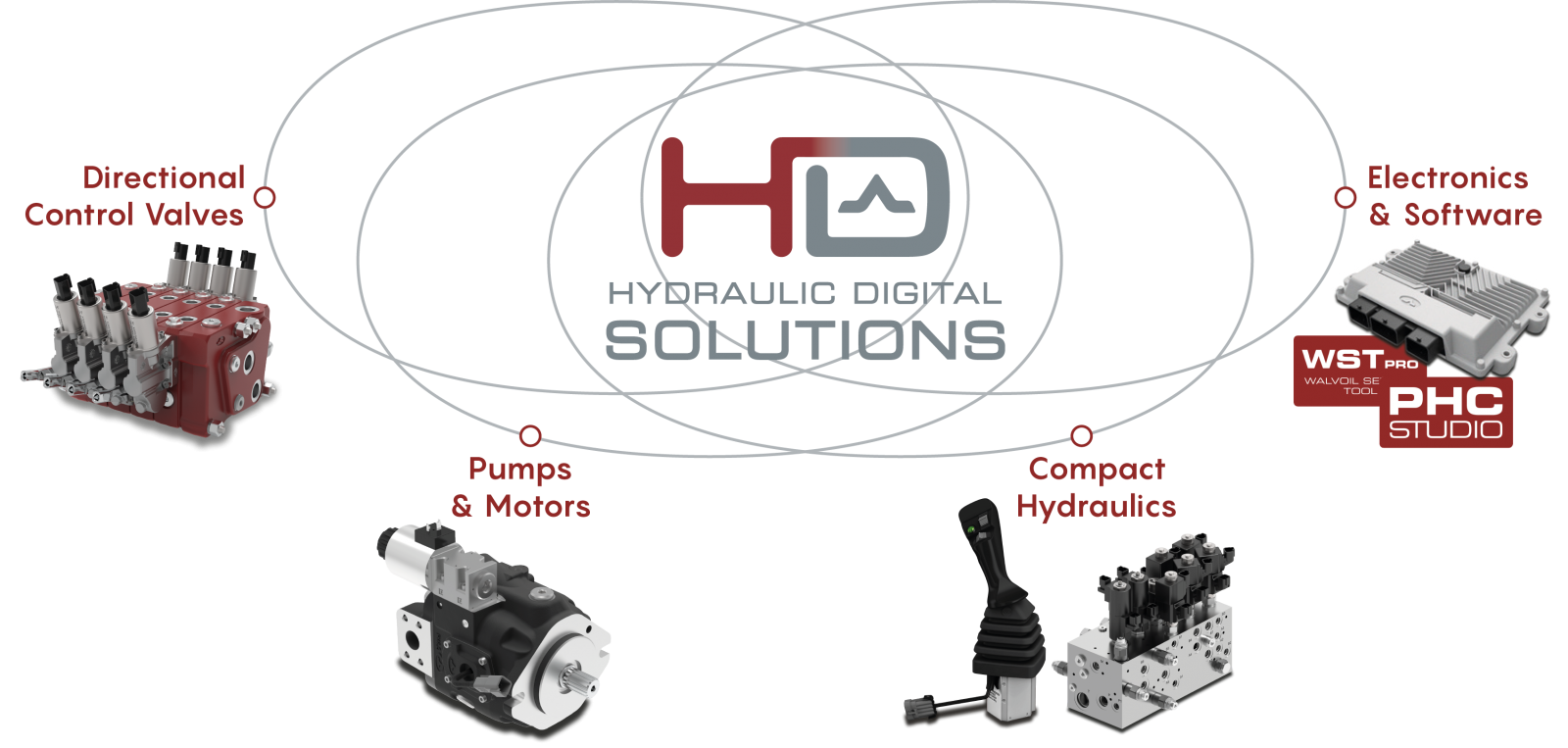

Walvoil has decided to focus on increasing the efficiency of the hydraulic system and its components with the new Hydraulic Digital Solutions product line: innovative solutions such as Adaptive Load Sensing (ALS) and EPX technology, which provide up to a 25% reduction in fuel consumption.

These solutions offer the best in terms of increased functionality and energy-efficient strategies thanks to ECUs (electronic control units) and proprietary software, which contribute to the construction of true mechatronic systems.

Fig. 2 – Energy savings with combined use of Walvoil ALS and EPX Hydraulic Digital Solutions

Walvoil will present its "Hydraulic Digital Solutions" in conjunction with the upcoming AGRITECHNICA trade show to promote dedicated solutions for the agricultural sector, which has undergone rapid evolution in recent years, with increasingly integrated electrification systems aimed at delivering energy-efficient performance.

In particular, the latest generation tractors are designed and manufactured with the aim of offering performance and functionality with high energy optimization and compliance with international safety regulations.

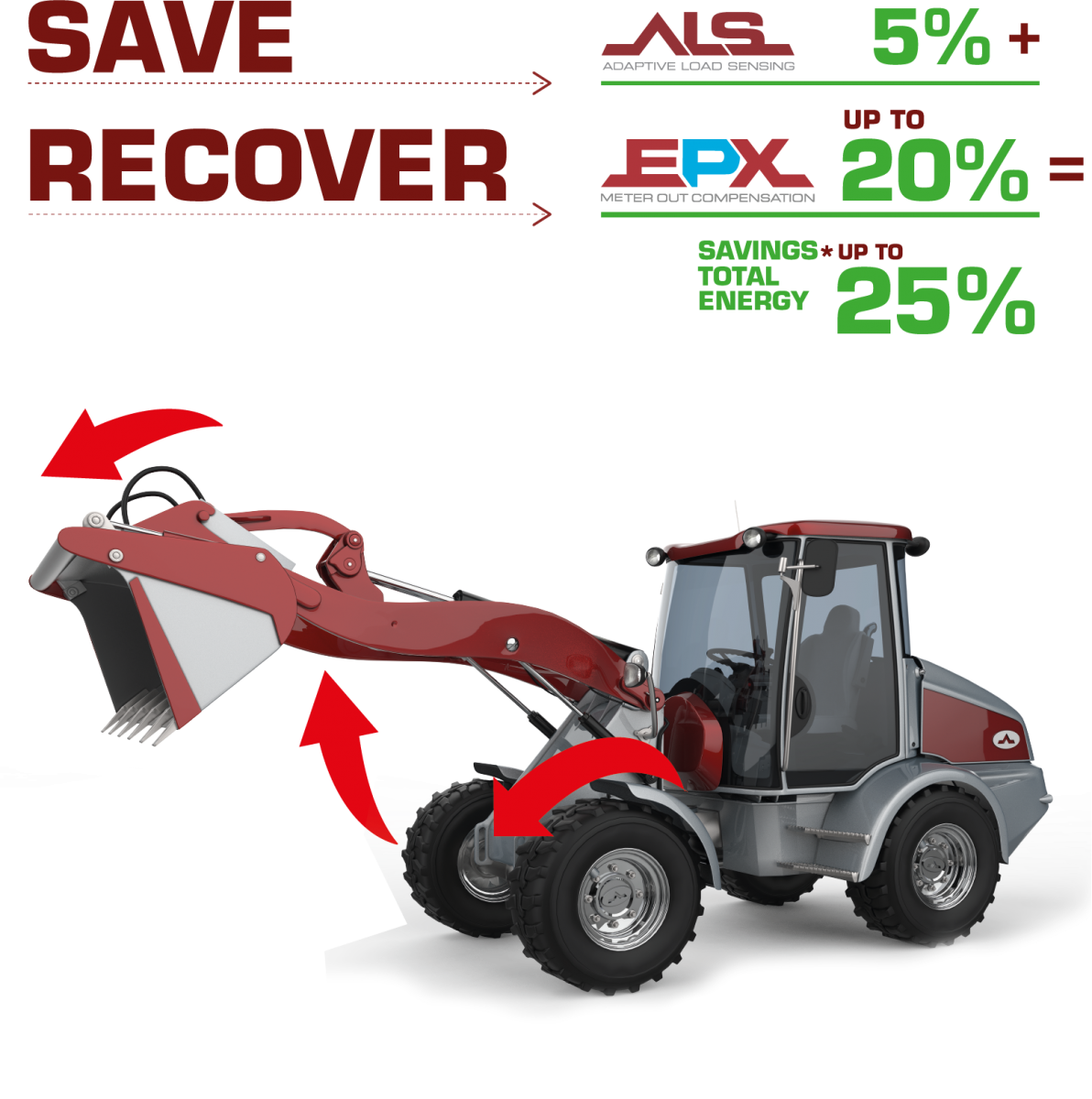

DPK120 Directional valves and supplements

In order to meet all these requirements and expand the range of responses for this application, Walvoil also introduces the new DPK120 directional valves. It is a pre-compensated sectional valve for open/closed center circuits, designed specifically for tractors and Front Loaders with flow rates up to 120l/min.

Fig. 3 – Walvoil DPK120 pre-compensated modular valve. Specific for tractors and Front Loaders.

Thanks to its flexibility and wide configurability, this new valve is compatible with all Walvoil products, providing complete solutions that can meet all requirements in terms of performance and low consumption.

The DPK120 is available with manual, hydraulic proportional, and electro-hydraulic controls; the new NG5 module allows electro-hydraulic CAN bus control of the spools quickly and precisely thanks to the integrated electronics (safety up to PLd/SIL) and contactless position sensor.

The contribution of Hitch Control

The integration of Hitch Control within a dedicated work section enables an automated system for controlling the machine's equipment, towed or pushed, replacing manual adjustment with more efficient and precise management. All adjustments, to compensate for unexpected changes in ground conditions, are made with the operator in the cab.

This not only allows automated and optimized control of machine performance, but also ensures a higher level of safety. Walvoil's Hitch Control reduces implement oscillations during the handling phase, decreasing wear and tear and making transport more comfortable for the driver. The system thus offers control solutions that contribute to making machines more competitive, improving the safety, comfort and productivity of customers' tractors.

Fig. 4 – Example of tractor solution with Hitch Control

Integration with the ALS system - Adaptive Load Sensing

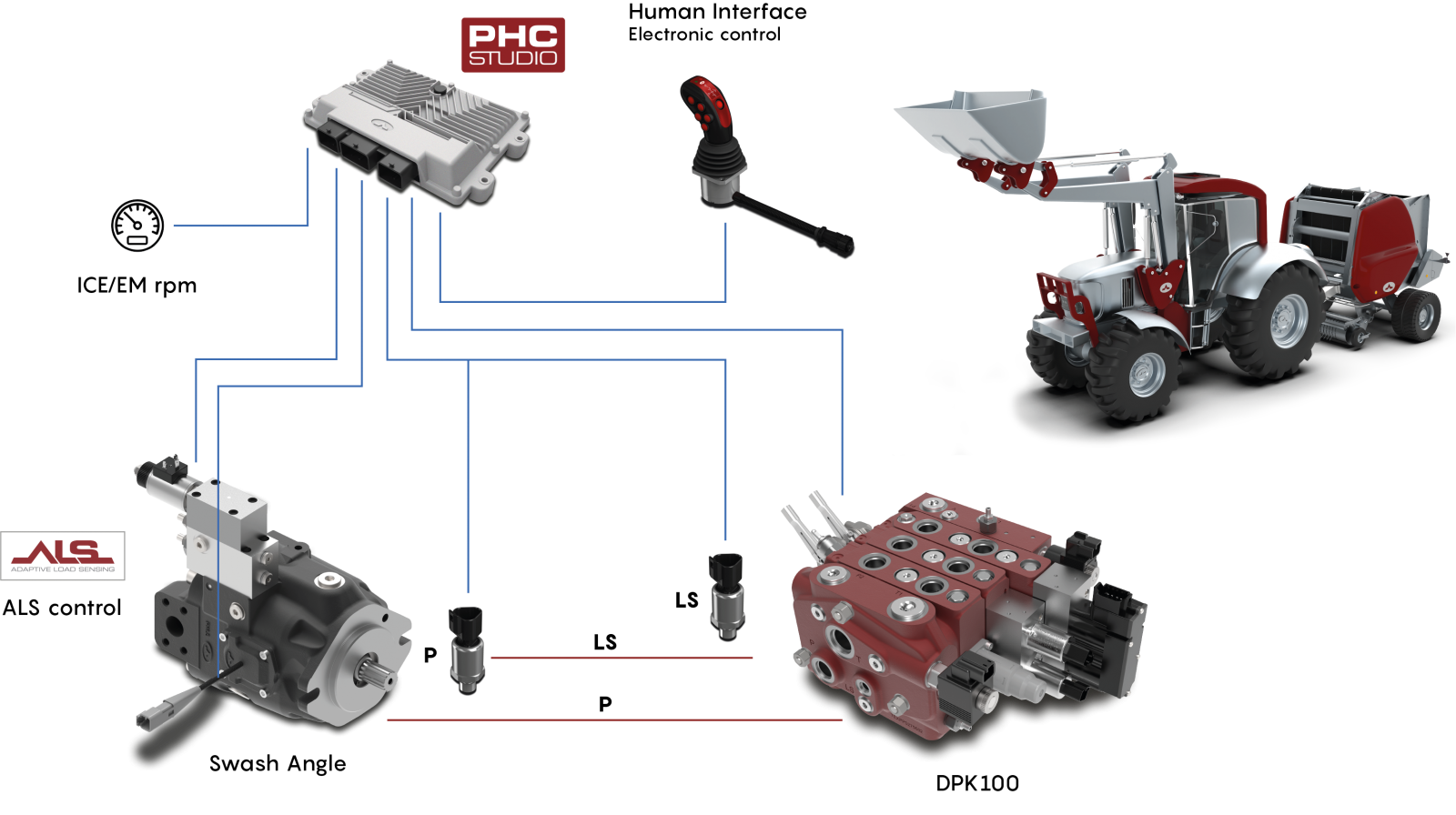

Speaking of further integrations, the DPK120 solution with Hitch Control is compatible with Walvoil's Adaptive Load Sensing: the Electronic Control and Flow Control logics thus reach new levels of performance in agriculture and consumption reduction.

The electronically controlled strategy of combining the DPK120 and PWLS pump with integrated ALS controller, then optimizes consumption by providing the flow rate defined through the customizable PHC STUDIO modular software developed by Walvoil. This feature allows for reduced energy consumption during low working speeds and more precise actuation when required.

The use of the new DJW electronic joystick, dedicated for ISOBUS systems, increases application safety up to Performance Level d/SIL 2.

Fig. 5 – ALS system - Adaptive Load Sensing, Electronic Control mode.

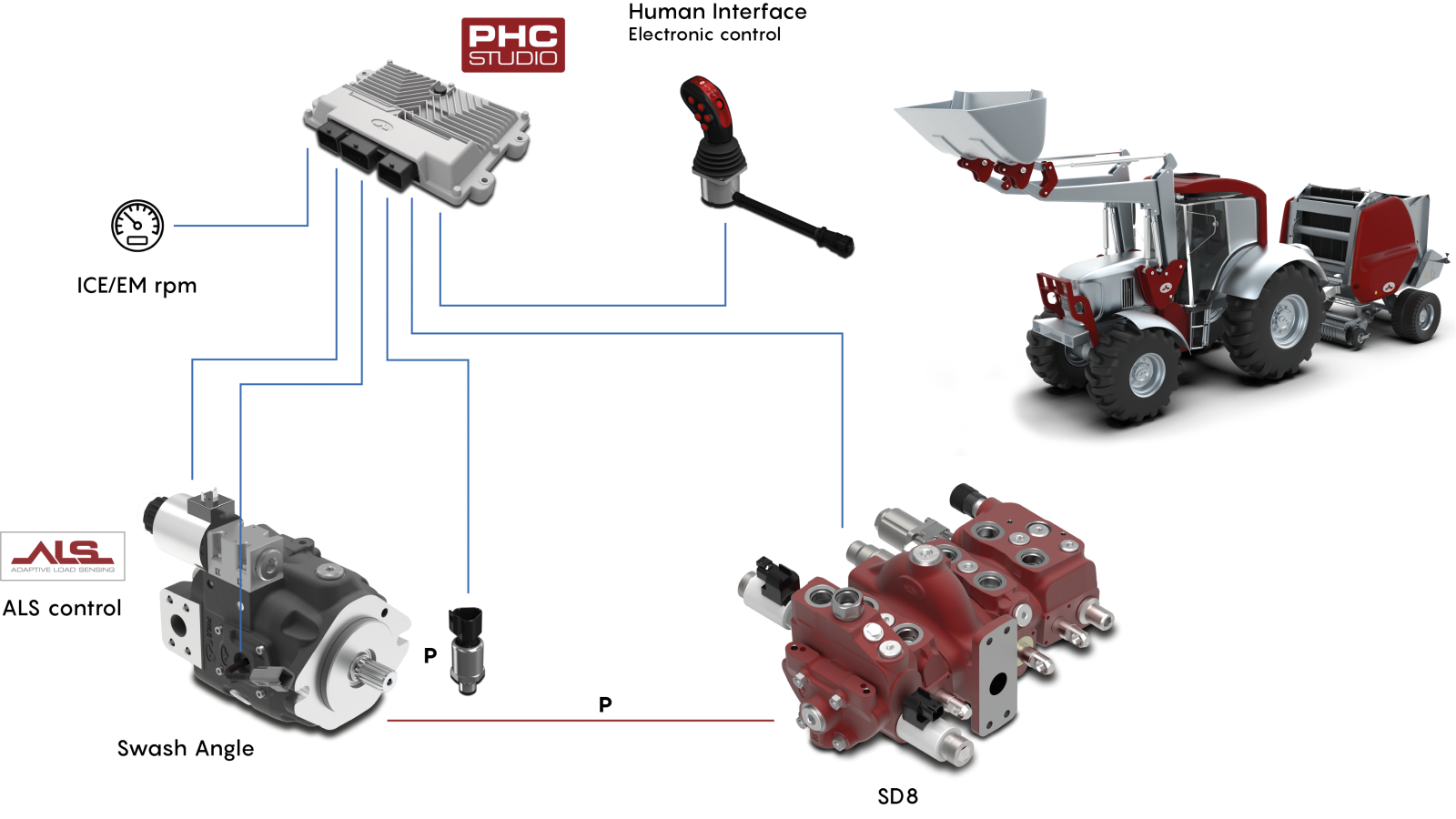

The Flow Control solution increases the degree of electrification and digitization of the system, as the configuration uses an electro-proportionally controlled open-center directional valves (e.g., a DPK120 or SD8 with integrated Hitch Control) with the PWLS pump equipped with ALS control. This allows the flow rate to be defined through software, taking into account single/simultaneous drives and inputs received from sensors.

This configuration provides greater stability and more precise regulation as it is independent of the classical hydraulic LS signal, which can be subject to external phenomena affecting performance and consumption.

Fig. 6 – ALS system - Adaptive Load Sensing, Flow Control mode.

The hydraulic energy recovery: the EPX technology

More and more manufacturers are moving their agricultural machinery toward electrification to reduce emissions and generate power energy in a green way. To advance this technological development, Walvoil is promoting the new EPX solution.

This new series of directional valves, based on 'meter-out compensation' technology, allows the management and recovery of hydraulic energy consumed during simultaneous drives of multiple functions or with inertial loads. This solution is very suitable for applications such as Front Loaders or Compact Wheel Loaders.

Tests carried out on a hybrid front loader for tractors, powered by the ICE primary engine and a secondary electric boost system, verified the effectiveness of the system with important results:

- 10% recovered energy that is dedicated to recharging the battery

- 8% energy savings thanks to the electric secondary boost system

- 16% energy savings thanks to the use of the R-line to power hydraulic functions.

Fig. 7 – EPX technology - 'meter-out compensation': test phase on lifters, example of system connection on machine, energy saving and recovery through R-line

To conclude, there are several proposals and solutions, within Walvoil's Hydraulic Digital Solutions, that are able to make available to an increasingly evolved agricultural machinery market, increasingly connected systems, often more compact and smaller in size, more efficient performance, greater safety and comfort for the operator, increased safety for those around the machine, and attention to sustainability and impact on the environment.

All with maximum customization based on the needs of the different manufacturers.

Walvoil Communication & Marketing

walvoil@walvoil.com

Tel. 0039.0522.932411

NEW PRODUCTS

NEW PRODUCTS